Target Groups - STEP7-1

- Technicians

- Engineering students

- Electricians

- Entry-level employees

- Commissioning engineers

- Experienced professionals

- Maintenance Engineers

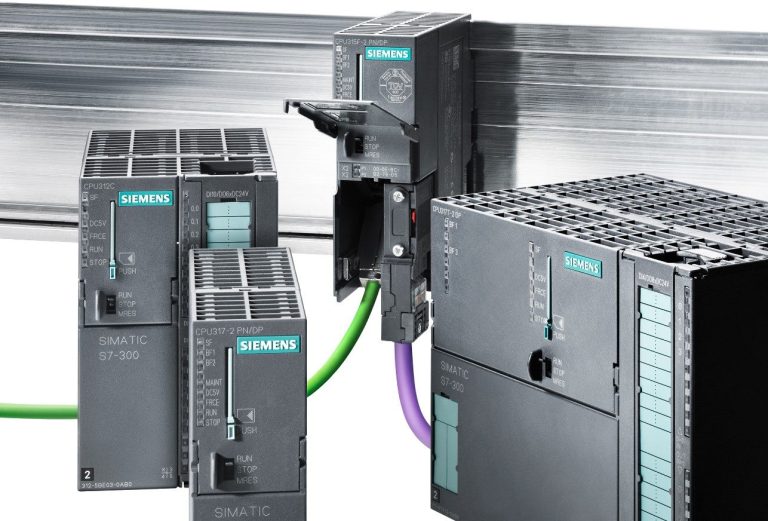

This course is designed for Electricians, Technicians and Engineers who are familiar with S7 PLCs, and are responsible for programming, installing, commissioning, maintaining and fault-finding Siemens Siemens S7-300 or S7-400 PLCs.

SIMATIC STEP7 Programming 1 (PLC S7-300/400)

- Introduction to the S7 family of controllers and concepts of TIA

- Project creation and operation using Simatic Manager

- Hardware configuration of S7 300/400 systems

- Application and use of the Symbol Editor

- Programming using the LAD/STL/FBD Editor

- Binary operations - N/O, N/C, Set, Reset, edge detection

- Digital operations - Accumulators, timers, counters, comparators

- Tools for troubleshooting and debugging

- Storing process Data in Data blocks

- The role of functions and function blocks

- Configuration and application of organisation blocks

- Documentation facilities including archive & retrieve options

- Deeper understanding of contents through practical exercises

Note: Training content can be tailored to meet your specific needs.

Target Groups - STEP7-2

- Technicians

- Engineering students

- Electricians

- Entry-level employees

- Commissioning engineers

- Experienced professionals

- Maintenance Engineers

This course is designed for Electricians, Technicians and Engineers who are new to S7 PLCs, and are responsible for programming, installing, commissioning, maintaining and fault-finding Siemens S7-300 or S7-400 PLCs.

SIMATIC STEP7 Programming 2 (PLC S7-300/400)

- Using struct programs as a method for program design

- Functions, function blocks and multi-instances ((with examples using IEC Timer/Counter)

- Using STAT and TEMP variables

- Creating and applying complex data structures

- Creating DBs using UDT’s and struct data types.

- Jump commands and Accumulator operations

- Configuration of Breakpoints as a debugging tool

- Memory Indirect addressing

- Using Error organization blocks to evaluate Profibus slave downtime

- Error management with error organisation blocks

- Analysing synchronous errors with organisation blocks

- Analysing S7 diagnostic data

- Analogue value processing

- Using PID Controllers

- Deeper understanding of contents through practical exercises

Note: Training content can be tailored to meet your specific needs.

©2025 Smartech Engineering Solutions. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.